★News navigation bar

- what is push button switch?

- Four types of push button switch

- How to install push button starter switch?

- How to choose a push button switch?

- Conclusion

what is push button switch?

A push button switch is an electronic component used to control the opening or closing of a circuit. It usually consists of a push button spring, internal contacts and a shell. When the button is pressed, the contacts close and current flows, thereby starting or stopping the device.

Three structures of push button switches

The structure of a push button switch can be basically divided into: push button switch contact surface, switch contact and push button switch housing.

Push button contact surface: the part that the user can press, the most common shapes are round/square/rectangular heads;

Switch contacts: the parts that connect the circuit to the switch, with normally open contacts or normally closed contacts available;

Push button switch housing: used to protect internal components, usually made of plastic or metal.

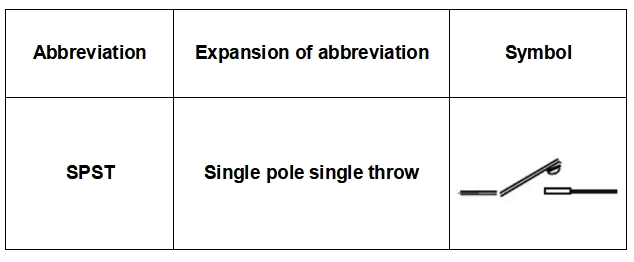

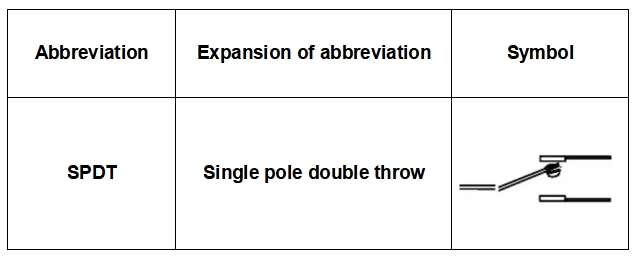

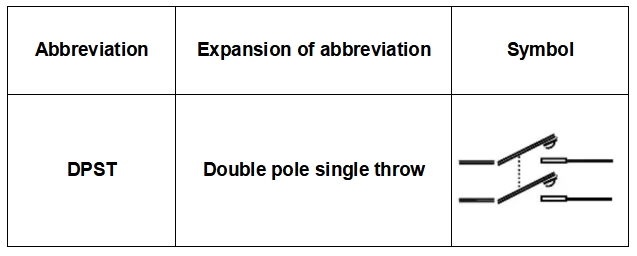

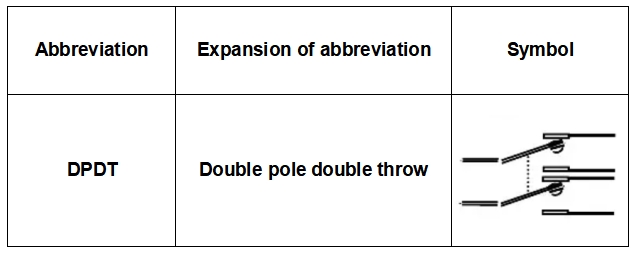

Four types of push button switch:Single pole single throw (SPST), single pole double throw (SPDT), double pole single throw (DPST), or double pole double throw (DPDT)

Single pole single throw type push button switches (SPST)

There are many types of push button switches, among which the single-pole single- (SPST) is the most basic type. The SPST switch has a set of contacts that are used to control the opening and closing of a circuit. When the button is pressed, the circuit is closed and the current flows; when the button is released, the circuit is opened and the current stops. This type of switch is widely used and is often seen in household lights and simple device switches. Due to its simple structure and low cost, the SPST switch is very popular in the market. Its advantages are high reliability and low failure rate, but its disadvantages are limited functions and can only control a single circuit.

Related product recommendations:

Single pole double throw type push button switches (SPDT)

Single-pole double-throw push button switch (SPDT), this switch has a set of contacts that can switch between two different circuits. When the button is pressed, circuit A is closed and circuit B is disconnected; when the button is released, circuit B is closed and circuit A is disconnected. The flexibility of SPDT switches makes them suitable for a variety of applications, such as selecting different power or audio input sources. In signal processing equipment, SPDT switches are often used to switch input signals. The advantage of this switch is its versatility and the flexibility to switch between different circuits, but its relatively complex structure also increases its risk of failure, and its price is usually higher than that of SPST switches.

Related product recommendations:

double pole single throw type push button switches(DPST)

Double-pole single-throw switch (DPST), this switch has two sets of contacts and can control two independent circuits at the same time. Take the reset button as an example: when the button is pressed, both circuits are closed; when the button is released, both circuits are disconnected at the same time. DPST switches are often used in electrical appliances that need to control multiple power sources at the same time, such as switches for two-phase circuits. This push button switch can control multiple circuits synchronously, improving the safety and convenience of the equipment. At the same time, it controls multiple circuits with one switch, reducing wiring complexity.

Related product recommendations:

double pole double throw type push button switches(DPDT)

The double-pole double-throw switch (DPDT) is the most complex switch with two sets of contacts. This switch can switch between two circuits and control the status of both circuits at the same time. When the button is pressed, circuit A1 is closed and circuit B1 is also closed, and when the button is released, circuits A2 and B2 are closed. DPDT switches are often used for forward and reverse control of DC motors and other equipment that requires complex switching. Its versatility allows users to control multiple circuits with one switch, and the operation is extremely convenient, but due to its complex design, the cost of DPDT switches is usually relatively high, and the installation and wiring are relatively complicated.

Related product recommendations:

How to install push button starter switch?

Step 1: Preparation for installing the button

Before installing a push-button start switch, it is very important to make adequate preparations. First, make sure the power is disconnected to prevent electric shock and equipment damage. Second, prepare the necessary tools and materials, including screwdrivers, cables, electrical tape, insulating gloves, and installation manuals or instructions (if available). Knowing the switch’s wiring diagram and circuit layout will help with subsequent installation.

Step 2: Select the installation location of the push button switch

Choosing a suitable installation location is a key step in the installation process. The push button switch should be placed in a location that is easy to operate and reach, ensuring that the user can press the switch conveniently. The installation height should be suitable for all potential users and take into account the actual needs of the usage scenario.

Step 3: Hold the push button switch

Secure the push button switch to the mounting hole location. Use screws and brackets to securely mount the switch to ensure its stability. Avoid using excessive force to avoid damaging the switch itself or the mounting surface.

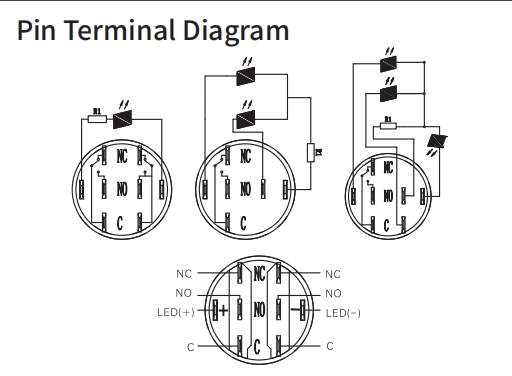

Step 4: Connect the Push Button Switch Cable

Connect the cables to the terminals of the push button switch according to the switch connection circuit diagram provided by the merchant. Make sure each cable is firmly connected to avoid looseness or short circuit. For switches with multiple contacts, it is necessary to confirm the function of each contact foot to ensure correct connection. Use electrical tape to insulate the exposed connection parts for increased safety.

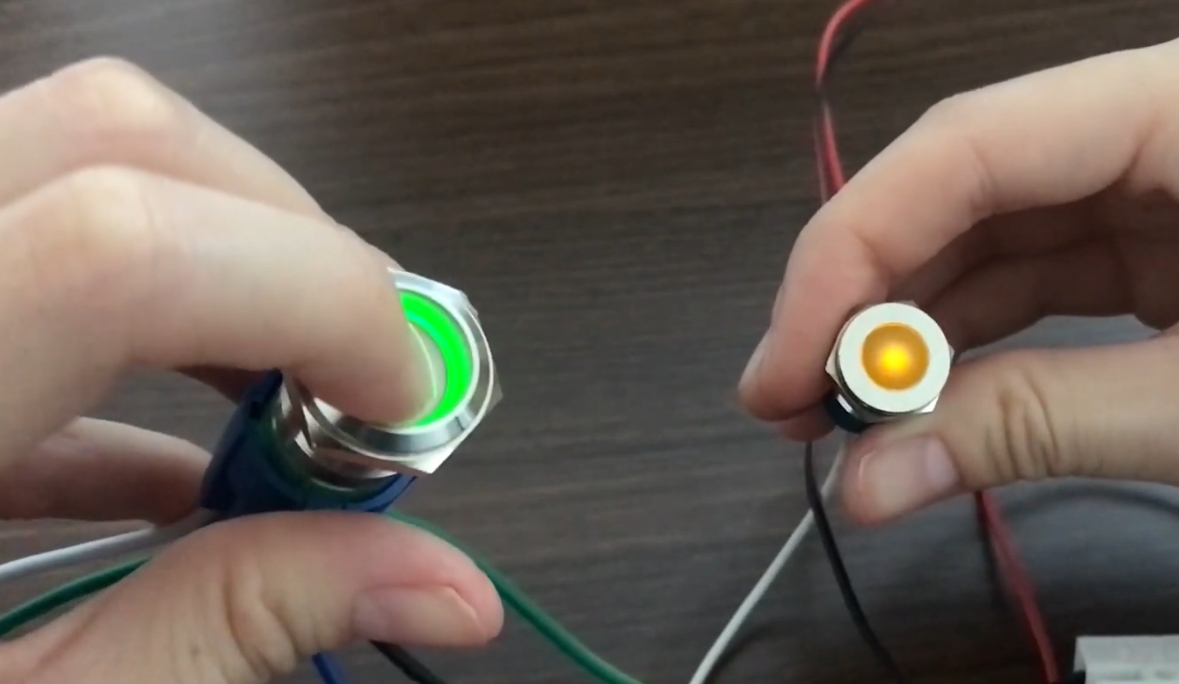

Step 5: Test the pushswitch functionality

First, restore power to the device and then press the button to check that the circuit is operating as expected. Make sure the switch is responsive and starts and stops the device properly. If you notice any problems, immediately remove power and check the connections to make sure everything is correct.

Step 6: Security Check

Finally, conduct a comprehensive safety check. Make sure all connections are secure, there are no exposed cables, and no loose parts. Check that the buttons operate smoothly and without obstructions. Maintaining a good installation environment can increase the service life and safety of the push button switch.

How to choose a push button switch?

1. Determine usage and functional requirements

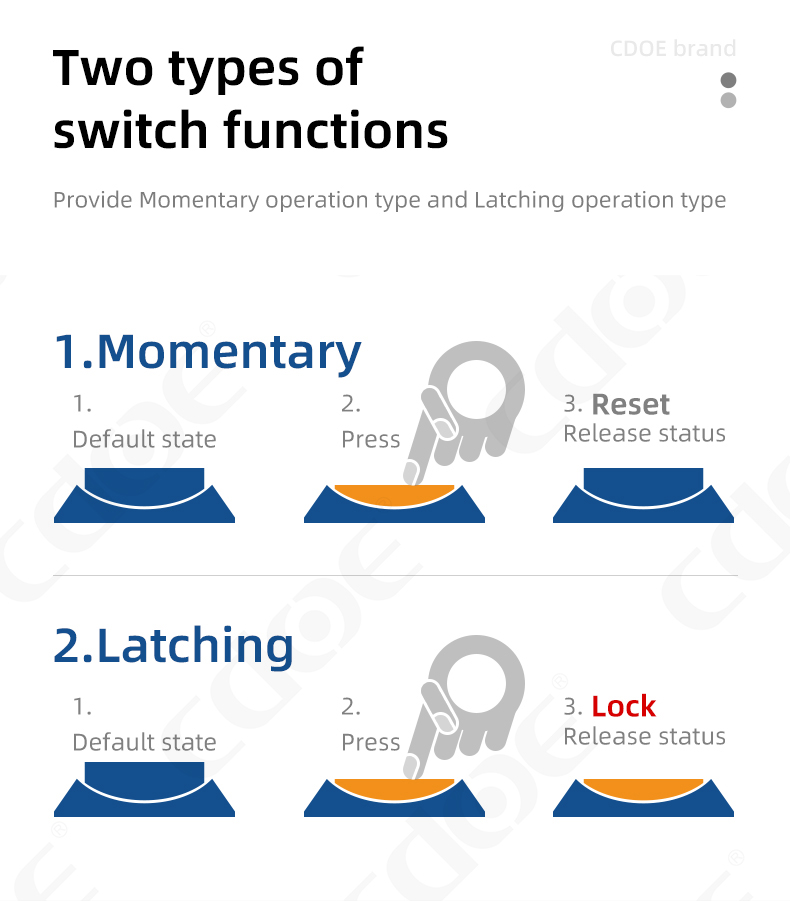

When choosing a push button switch, you must first clarify the purpose of the device and the required functions. For example, if the device requires simple on-off control, you can choose a single-pole single-throw (SPST) switch; if you need to switch between two circuits, you can choose a single-pole double-throw (SPDT) switch. The most critical functions are momentary type and latching type. For momentary buttons, after releasing the button, the circuit will return to the default state. For latching buttons, after releasing the button, the state when pressed can still be maintained, and the button needs to be pressed again to restore it. Understanding the operating frequency and usage scenarios of the device will help you choose the appropriate switch type.

2.Consider electrical parameters

Checking the electrical parameters of a push button switch is an important step in the selection process. Make sure the voltage and current rating of the button matches the electrical specifications of the device. Excessive voltage or current can cause damage to the switch, so it is critical to select a switch with the appropriate electrical specifications.

3.Environmental adaptability

When selecting a push button switch, you also need to consider its operating environment. If the switch will be used in a humid, dusty or extreme temperature environment, you should choose a switch with waterproof (such as IP65/IP67 or higher) and dustproof characteristics. This can improve the durability of the switch and ensure that it can work properly under harsh conditions.

4.Convenience of use

Choose a button switch that feels good and is easy to press, especially in frequent use. The size and shape of the button should also adapt to the user’s operating habits to ensure comfort and safety during user use.

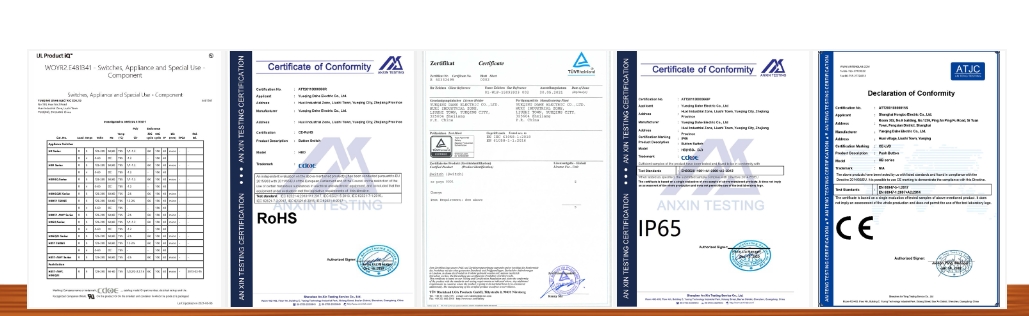

5.Product quality/certification requirements

Choosing a well-known brand and high-quality push button switch can improve the reliability of the product. Usually, push button switches that meet high-quality standards can be screened by checking user evaluation feedback, product certification certificates, and warranty policies. High-quality push button switches are not only durable, but also reduce failure rates and provide better user experience.

6.Procurement cost budget

Finally, cost considerations are also an important factor when choosing a push button switch. Choose the right product according to your budget, but don’t just pursue a low price and ignore product quality. Try to find the best balance between performance and price within your budget.

Conclusion

Push button start switches are a very important electrical component in modern electronic devices and industrial applications. By understanding the different types of push button switches and their characteristics, users can make choices based on specific needs. During the installation process, following the correct steps and safety measures will not only ensure the normal operation of the equipment, but also extend the service life of the switch. In order to help you find the push button switch that best suits your equipment, we offer a variety of models and specifications to meet the needs of different application scenarios. If you are interested in our products or have any questions, please do not hesitate to contact us immediately! Our professional team will wholeheartedly provide you with advice and support to ensure that you make the best choice. You can easily get the push button switch you need by filling out the inquiry form or placing an order directly. We look forward to working with you to jointly promote the success of your project!